Nucleating agent GX-2

The GX-2 belongs to the third-generation nucleating transparent agent of dibenzylidene sorbitol (DBS) polypropylene, which promotes the crystallization of polypropylene resin by providing crystal nucleus, and micronizes the structure of crystal grains, to achieve the purposes of improving the rigidity, thermal deformation temperature, dimensional stability, transparency and surface luster of products. With the chemical composition of DMDBS, the third-generation DBS nucleating transparent agent GX-2, compared to the DBS, the first generation product, and the MDBS, the second generation product, is more transparent, in addition to the substantially improved thermal stability and smell, basically solving the problems of scale depositing and pungent odor during processing. Thus, it has become a universal transparent agent for modifying PP today. As a type of DBS nucleating agent, GX-2 is dissolvable in polypropylene under processing temperature. With the melt temperature of resins constantly decreasing, first the nucleating agent is crystallized and forms nanoscale "linear" crystals, inducing the nucleation and crystallization of polypropylene melts, and increasing the crystallinity of products while micronizing the structure of crystal grains, so as to achieve the purposes of improving the rigidity, thermal deformation temperature, dimensional stability, transparency and surface luster of products. The nucleating agents dissolvable in resin are also known as "soluble nucleating agents".

The technical innovation of this product is to add special component which facilitates the dispersion of nucleating agent, thus improving the evenness of the dispersion of the product in polypropylene melt.

Chemical name:

1,3 : 2,4-Bis (3,4-dimethylobenzylideno) sorbitol

Structural formula:

Molecular formula:C24H30O6

CAS No:

135861-56-2

Application characteristics:

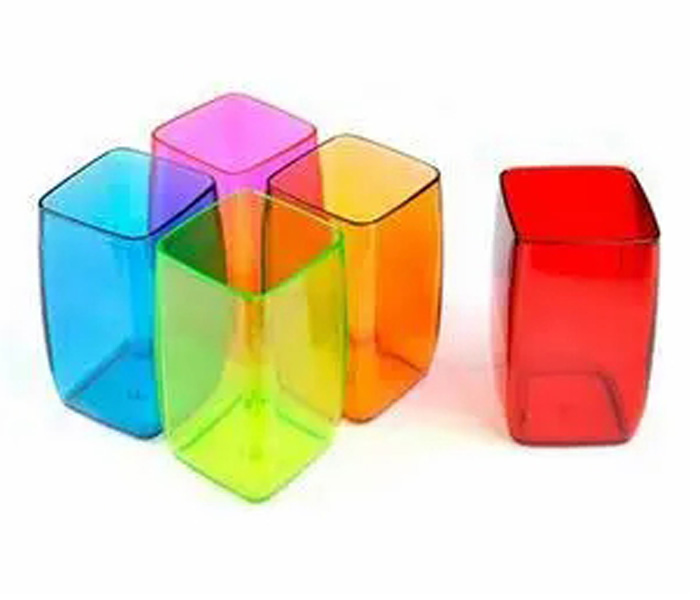

The nucleating transparent agent GX-2 is mainly applicable to polypropylene homopolymer, polypropylene random copolymer and LLDPE film. It can directly mix with resin for injection molding or extrusion molding, or mix with other additives first to form transparent masterbatch (2.5-5%), and then mix with ordinary polyolefin. In polyolefin, 0.1-0.3% nucleating transparent agent GX-2 is added; PP powder can be put into process after adding the nucleating transparent agent GX-2; while PP granules can evenly mix with a small amount of white oil, and then be added with nucleating transparent agent GX-2 dispersedly. Fully stir the mixture. It is recommended to add 20-40ml white oil for every 50kg polypropylene. The nucleating agent GX-2 can also be used together with other plastics additives.

Health and safety: the GX-2 product can be used in food packaging materials. Avoid dust and keep away from fire sources during operation and use.

Packaging: the outer packaging is carton, 10kg/ carton, and the inner packaging is three in one compound bag, 5kg / bag; or as required by customers.

Storage precautions: this product should be kept in a cool and dry place. If the product does not run out, be sure to tighten the bag. Sealed products have three years of shelf life.

Quality standard: executive standard Q/ITCL6

Technical requirements:

| Item | Index |

| CAS | 135861-56-2 |

| Appearance | White powder without odor |

| Melting point ℃ | 245~255 |

| Loss on drying ≤ % | 0.5 |

| Granularity ≥ | 325 meshes |